24-hour online consultation

|

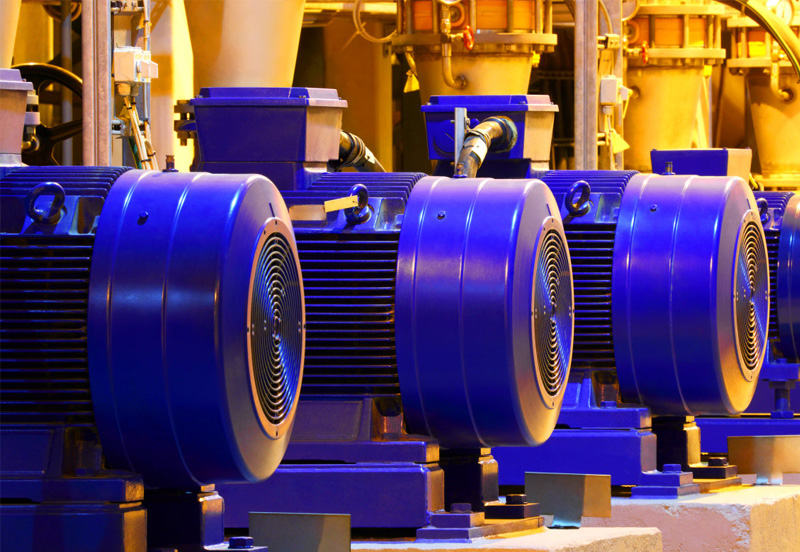

Industrial pumpsThe pump industry includes slurry pumps, clear water pumps, submersible pumps, pipeline pumps etc. The working environment is relatively harsh, dusty, humid, high and low temperature. The pump industry requires bearings with technical characteristics such as low noise, low vibration, low energy consumption, high efficiency and corrosion resistance, and we can provide rolling bearings and technical solutions for all types of sealed structures.

Industrial pumps often operate in harsh or even extreme conditions with demanding duty cycles, resulting in unnecessary downtime, reduced performance and shorter machine life, which can negatively impact your return on investment, poor pump maintenance strategies can result in a 10% to 15% loss in efficiency, by adopting the right maintenance strategy you will be able to significantly reduce life cycle costs and industrial pump downtime time. Modern society requires reliable and efficient pump systems, and the challenge for today's pump O&M staff is to find ways to reduce the total cost of ownership while complying with increasingly stringent environmental and safety regulations. Pump manufacturers are striving to increase the time between failures while optimising energy consumption throughout the pump's life cycle, as energy accounts for 45% of the total cost of ownership. Whether you operate a municipal water supply, pump oil from the seabed or pump corrosive liquids in a chemical plant, we will design products and services to meet the needs of your pump application. Proper lubrication can prevent excessive bearing wear, reduced bearing operating life and premature failure. We can help you simplify your design and production processes with relubrication-free solutions, benefiting from reduced maintenance and reduced grease or oil consumption. This leads to a lower cost of ownership and more sustainable operation. |